ZnO has a crystal structure similar to that of GaN and ZnS, and has extremely high covalent character among the oxide and, hence, it is atypical of wide gap semiconductors. Consequently, application to light emitting diodes, electroluminescence devices and semiconductor laser devices has been difficult. Naturally, these are not inorganic semiconductor quantum dots and, therefore, material insulation and matching of energy level are hard to attain.

In the field of fabricating core-shell quantum dots having zinc oxide as the core, prior techniques that successfully attained emission clearly from the quantum confining levels are limited to those utilizing amorphous silicon oxide or organic resin used as the shell. Specifically, the material is required to attain lattice matching with zinc oxide as the core material in its growth, to satisfy the band structure described above, and to have a characteristic not prone to defect formation.

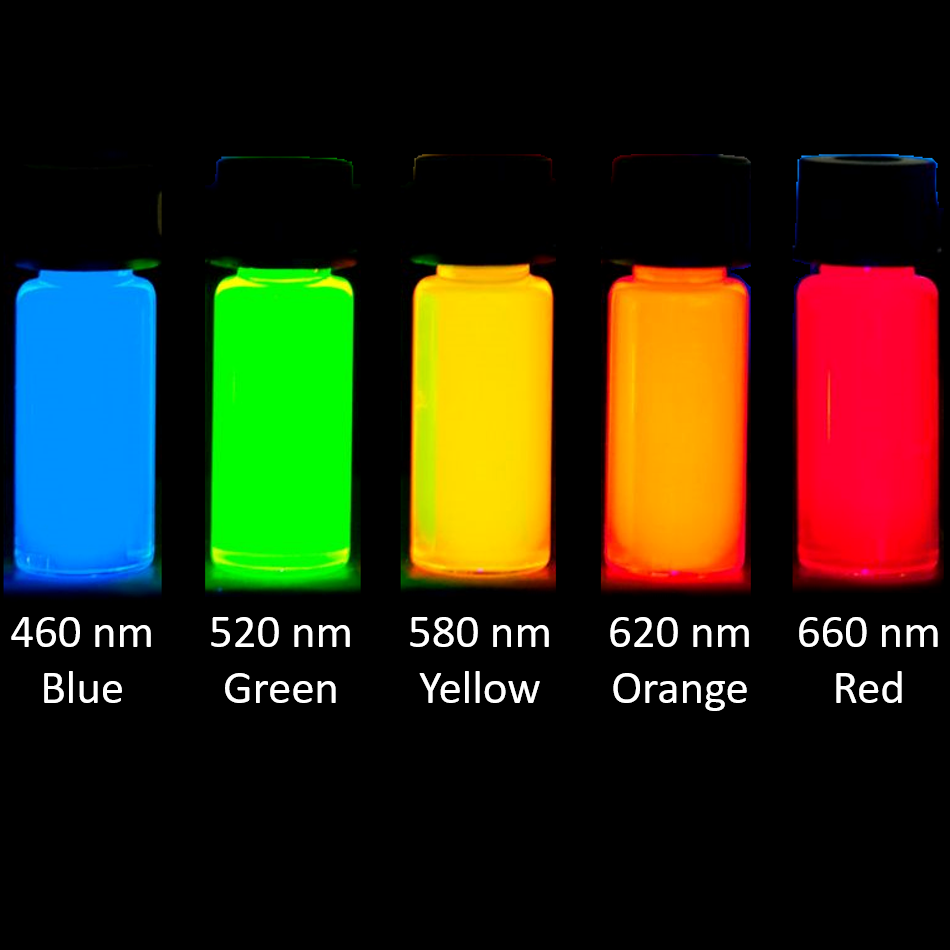

In such a process, it is essential that the shell material, which corresponds to the potential barrier layer, is grown epitaxially on zinc oxide as the core material and grown substantially without defect formation so that transition probability through defect level does not counter transition probability between quantum confining levels. When electronics devices are formed by arranging many quantum dots of uniform size on an amorphous or poly-crystalline substrate or base material, use of colloidal core-shell quantum dots synthesized by wet chemical process of, for example, sol-gel method has an overwhelming advantage. The material must be a wide gap semiconductor having energy of the bottom of the conduction band higher than the quantum confining level of electrons formed in the conduction band of zinc oxide and energy of the top of the valence band lower than the quantum confining level of holes formed in the valence band of zinc oxide. Characteristics required of the material are as follows. That is, it is necessary to form a three-dimensional quantum well structure without any deactivation path. In order to form the quantum dot material from inorganic material, however, it is necessary to coat the nano particle with a material having certain characteristics as a potential barrier layer or a distributed matrix of the zinc oxide nano particle and, in addition, to passivate surface level of zinc oxide. Attempts have been made to produce material (a so-called quantum dot material) that can provide near-ultraviolet emission having desired emission peak wavelength and desired half width, utilizing the quantum size effect, by controlling the size of zinc oxide nano particles. In other words, when a nano-sized semiconductor is formed, the bandgap of the semiconductor becomes larger due to quantum size effect, and emission energy due to recombination between the excited electron in conduction band and the hole in valence band increases as the semiconductor size decreases. Zinc oxide (ZnO) having bandgap energy of about 3.37 eV and exciton binding energy as large as 60 meV is considered promising in industrial applications, particularly in an application to self-emitting electronics devices, as a phosphor or light emitting material of near-ultraviolet light (wavelength of about 390 nm) that emits light stably even at room temperature.Ī phenomenon has been known generally that, when the size of semiconductor is reduced to be comparable to the wavelength of electron or hole wave function in the semiconductor, so-called quantum confining levels appear in conduction band and valence band and the electrons and holes increase ground state energy. Further, the present invention relates to ultraviolet fluorescent fine particles emitting light in ultraviolet region. More specifically, it relates to quantum dot fluorescent material. The present invention relates to light emitting material.

0 kommentar(er)

0 kommentar(er)